SKU 310164

Category Greases

Extreme Synthetic Grease

ZERAX 5502

Extreme Synthetic Grease Advantages

Zerax 5502 synthetic grease has much lower friction and higher load carrying properties compared to the properties of ordinary petroleum base oils. At the same time, it offers long-term operating performance even when operated over wide temperature ranges. In this way, it is seen as a product that can be safely preferred even at very high or very low temperatures.

Even if large amounts of water are mixed into the synthetic grease, there is no loss of consistency. Due to the nature of the calcium sulfonates it contains, it shows excellent oxidation and corrosion resistance even in the presence of seawater.

They show full durability in high pressure environments.

Resistant to many chemicals and water types

It is highly resistant to oxidation and aging.

Extreme Synthetic Grease Features

- Synthetic grease has a wide operating temperature range.

- It is a product with high pumpability.

- Extra resistant against rust and corrosion.

- Retention feature is at maximum level.

- The cost of synthetic grease is much lower than standard greases due to the long life of the lubrication periods.

Extreme Synthetic Grease Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

YOU MAY

ALSO

INTEREST

PRODUCTS

Extreme Synthetic Grease Tech Data

| ANALİZLER | STANDART | BİRİM | SONUÇ |

|---|---|---|---|

| Color | Blue | ||

| Appearance | Homogeneous | ||

| Thickener | Calcium Sulfonate Complex | ||

| Base Oil | Synthetic | ||

| Base Oil Viscosity (cst) at 40 °C | ASTM D445 | cst | 460 |

| Temperature Range | °C | -40 / 205 | |

| NLGI Class | 1 / 2 | ||

| Dropping Point | ASTM D2265 | °C | >320 |

| Seperation from Oil (% weight) 30 hours / 100 °C | ASTM D6184 | %wt | %3,70 |

| Copper Corrosion (100 °C - 24 hours) | ASTM D130 | Max 1 b | 1 a |

| Four Ball EP Test 10 sec. / 1770 rpm Speed (kg) | ASTM D2596 | Kg | > 400 |

| Four Ball Test 1 h./1200 rpm Speed, 40kg (392N) | ASTM D2266 | mm | 0,5 |

| Water Spray (% weight) | ASTM D4049 | %wt | %15 |

| Rust Test | ASTM D1743 | Pass |

Extreme Synthetic Grease Frequently Asked Questions

Contact Form

MADE IN

TÜRKİYE

FOR ALL ORDERS

FREE SHIPMENT

ON-SITE PROBLEM

DETECTION

TECHNICAL

CONSULTING

Zerax 5502 synthetic grease does not contain any heavy metals such as lead, which is known to be harmful to human health and the environment. The product provides excellent protection against rust in aqueous and salty water environments. It also exhibits superior performance against torques with low temperatures. In addition to all these, it offers excellent pumping properties.

WHAT IS SYNTHETIC GREASE?

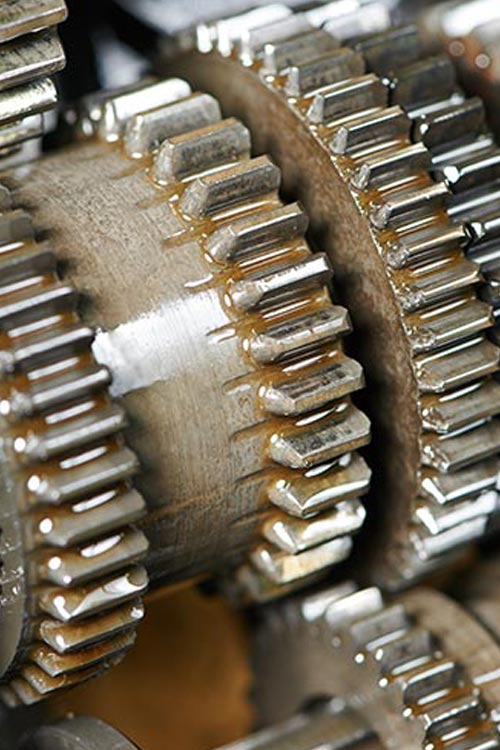

Synthetic grease has conventionally been the most common lubricant for rotating machine components such as bearings. It is mainly composed of a lubricant and a thickener. The thickener acts as a carrier for the lubricating component, holding the lubricant between its cage-like fibers.

As temperatures rise during operation, oil leaks from the grease and lubricates the mating and sliding surfaces inside the bearings.

Both conventional petroleum-based greases and synthetic greases use thickeners made of a metallic substance such as lithium or calcium. These can be formulated with additives to meet extreme pressures, extreme vibration or other demanding requirements.

The difference between conventional grease and synthetic grease can be recognized in the lubricant. Conventional greases use a petroleum-based product such as mineral oil. Synthetic greases use a synthetic lubricant such as silicone. As a result, synthetic grease can endure extreme temperatures and maintain its lubricating effectiveness better than conventional greases.

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.

SKU 310164

Category Greases

Extreme Synthetic Grease

ZERAX 5502

THICKENER

Calcium Sulfonate Complex

BASE OIL

Synthetic

NLGI

1, 2

1 kg, 20 kg, 200 kg

1-3 Weeks

-

MADE IN

TÜRKİYE

-

FOR ALL ORDERS

FREE SHIPMENT

-

ON-SITE PROBLEM

DETECTION

-

TECHNICAL

CONSULTING

Extreme Synthetic Grease Advantages

Zerax 5502 synthetic grease has much lower friction and higher load carrying properties compared to the properties of ordinary petroleum base oils. At the same time, it offers long-term operating performance even when operated over wide temperature ranges. In this way, it is seen as a product that can be safely preferred even at very high or very low temperatures.

Even if large amounts of water are mixed into the synthetic grease, there is no loss of consistency. Due to the nature of the calcium sulfonates it contains, it shows excellent oxidation and corrosion resistance even in the presence of seawater.

They show full durability in high pressure environments.

Resistant to many chemicals and water types

It is highly resistant to oxidation and aging.

Extreme Synthetic Grease Features

- Synthetic grease has a wide operating temperature range.

- It is a product with high pumpability.

- Extra resistant against rust and corrosion.

- Retention feature is at maximum level.

- The cost of synthetic grease is much lower than standard greases due to the long life of the lubrication periods.

Extreme Synthetic Grease Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

IN THESE PRODUCTS

YOU MAY BE INTERESTED

Extreme Synthetic Grease Tech Data

| ANALİZLER | STANDART | BİRİM | SONUÇ |

|---|---|---|---|

| Color | Blue | ||

| Appearance | Homogeneous | ||

| Thickener | Calcium Sulfonate Complex | ||

| Base Oil | Synthetic | ||

| Base Oil Viscosity (cst) at 40 °C | ASTM D445 | cst | 460 |

| Temperature Range | °C | -40 / 205 | |

| NLGI Class | 1 / 2 | ||

| Dropping Point | ASTM D2265 | °C | >320 |

| Seperation from Oil (% weight) 30 hours / 100 °C | ASTM D6184 | %wt | %3,70 |

| Copper Corrosion (100 °C - 24 hours) | ASTM D130 | Max 1 b | 1 a |

| Four Ball EP Test 10 sec. / 1770 rpm Speed (kg) | ASTM D2596 | Kg | > 400 |

| Four Ball Test 1 h./1200 rpm Speed, 40kg (392N) | ASTM D2266 | mm | 0,5 |

| Water Spray (% weight) | ASTM D4049 | %wt | %15 |

| Rust Test | ASTM D1743 | Pass |

Extreme Synthetic Grease Frequently Asked Questions

Contact Form

Zerax 5502 synthetic grease does not contain any heavy metals such as lead, which is known to be harmful to human health and the environment. The product provides excellent protection against rust in aqueous and salty water environments. It also exhibits superior performance against torques with low temperatures. In addition to all these, it offers excellent pumping properties.

WHAT IS SYNTHETIC GREASE?

Synthetic grease has conventionally been the most common lubricant for rotating machine components such as bearings. It is mainly composed of a lubricant and a thickener. The thickener acts as a carrier for the lubricating component, holding the lubricant between its cage-like fibers.

As temperatures rise during operation, oil leaks from the grease and lubricates the mating and sliding surfaces inside the bearings.

Both conventional petroleum-based greases and synthetic greases use thickeners made of a metallic substance such as lithium or calcium. These can be formulated with additives to meet extreme pressures, extreme vibration or other demanding requirements.

The difference between conventional grease and synthetic grease can be recognized in the lubricant. Conventional greases use a petroleum-based product such as mineral oil. Synthetic greases use a synthetic lubricant such as silicone. As a result, synthetic grease can endure extreme temperatures and maintain its lubricating effectiveness better than conventional greases.

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.