OILS

Used in many areas of industry, lubricants play an important role in slowing down friction. Whether in the automotive, steel, wind energy or mining sectors, they protect equipment and keep it running smoothly for longer.

ARMONİ

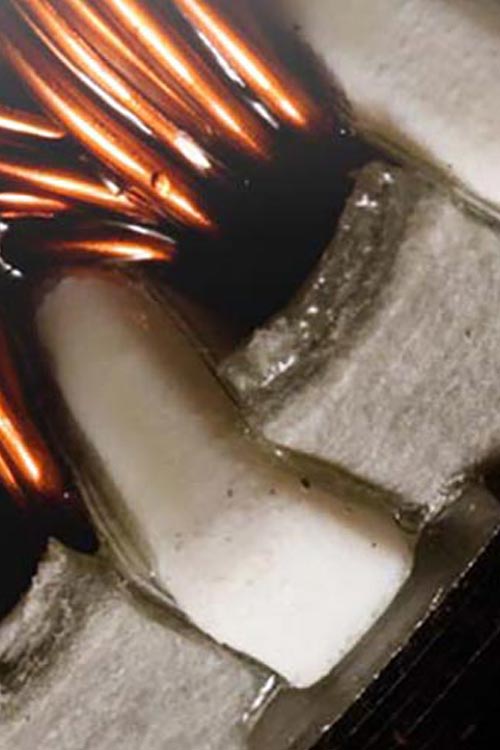

Circular Knitting Machine Oil

Corfin Lubrication, the leading brand of specialty lubricants in Turkey, received full marks from its customers by developing Armoni 22/32/46 series oils with high performance as sinker and needle oil for circular textile knitting machines.

MADE IN

TÜRKİYE

All Orders

Free Shipment

On-site Problem

Detection

Technical

Consulting

Frequently Asked Questions About Lubricants

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

What is Mineral Oil and How is it Obtained?

Oil is generally obtained by combining base oils with different viscosities and various additives. These additives may vary according to the properties expected from the lubricants.

For this very reason, it is very important to determine the structural characteristics of the additives to be used during production. The base oil is refined and becomes part of the composition in the form in which the oil is extracted from the ground, i.e. crude.

Intended Use of Mineral Oil: No matter how flawlessly the parts of the machines are produced, it is very difficult to ensure a perfect gloss and smoothness on the surfaces of the parts. Indentations and protrusions called asperities on the surfaces of these parts, which can only be seen with a microscope, will definitely occur.

These indentations are the result of two surfaces coming into contact with each other continuously over a long period of time. They also cause resistance to surface movement and increased friction in parts that are not lubricated.

The main purpose of using lubricants is to reduce this friction in the best possible way. The lubricant forms a film on the surfaces that are in constant contact with each other and helps the parts to move much more easily by moving the two solid objects away from each other in this way.

How is Lubricant Production Done?

One of the products produced by the refining of crude oil is a lubricant called mineral oil. During its production, after the oil refining process, it is again subjected to special processes and some base oils are obtained as raw materials.

Oil is obtained by mixing base oils with different viscosities with various additives selected to meet the expectations. It is critical to choose the right lubricant for the intended use.

What are the Differences Between Oils?

It is possible to find many types of lubricants in the sector and the raw material used in all of these lubricants is the same. However, base oils may differ due to the different materials used in the production of the oils.

There are two reasons for these differences. Differences in the chemical properties of the base oils used in lubricant production, the amount and types of solids used are the factors that reveal the distinction.

Classification of Oils

Lubricants are classified in two different groups as “Mineral Base Oils” and “Synthetic Base Oils” according to the chemicals and additives they contain.

Mineral Base Oils (H3)

It is possible to examine them in 3 groups in terms of their chemical structure and the properties they add to oils.

- Aliphatics: Organic compounds and derivatives that contain a straight or chained skeleton in their molecular structure, formed by covalent bonding of various atoms to each other.

- Paraffinic (H5): Paraffinic oils are refined through hydrocracking process or extraction method. They show high flash points, low volatility, good color stability. These oils are a good choice for applications requiring stability in high temperature environments and low color.

- Naphthenic : Naphthenic oils have a wide range of application options among the lubricant options. This oil has a wide viscosity range and also has flash, payback power and color refining properties.

- Aromatics (H4): In paraffinic oil production, aromatic oils are obtained as a result of aromatic extraction. They have dark color, low aniline points, relatively high flash points and high aromatic content. Aromatic oils are used in the lubricant industry in normal applications where a degree of payback is desired for high softening or where they have a plasticizing effect.

- Aliphatic and Aromatic: It is not possible to ensure complete shine and smoothness even on the surfaces of perfectly manufactured parts. For this reason, mineral oil must be used to ensure that the parts are shiny and smooth.

Aliphatic compounds are reactants such as alkanes, alkenes, alkynes or their derivatives. Aromatic compounds are compounds such as benzene derivatives or benzene heterocyclic.

Note: Oxidation means that the oil starts to sludge. If the lubricant starts to show oxidation, it must be replaced.

Synthetic Base Oils

The properties of mineral base oils are limited by the structural properties of crude oil. At the same time, the rapid increase in oil prices has been observed in recent years due to the decrease in oil production worldwide.

Today, due to the rapidly developing technology, there is a need for lubricants that can operate under much more difficult conditions. For this reason, studies on the use of synthetic lubricants are increasing rapidly day by day.

How are Synthetic Oils Obtained?

Synthetic oils are obtained as a result of non-petroleum based chemical synthesis methods. At this stage, hydrocarbon molecules are designed to be similar to each other in terms of shape and size to form a synthetic structure using a chemical process.

The structure of synthetic oils is carefully regulated. In this way, friction level is minimized, temperature is reduced, wear is reduced and energy saving is maximized. Thanks to all these features, synthetic oils in mineral oil are preferred for their superior properties.

Düşük sıcaklıklarda kolay akarlar ve yüksek sıcaklıklarda da incelmezler. Oksidasyon özelliklerinin yüksek olması ve ısıl mukavemetleri sayesinde makinelerin kullanım ömrünü önemli ölçüde uzatırlar.

Synthetic oils are produced in a laboratory environment using a special technology. They are resistant to much higher and lower temperatures than mineral oils, one of the mineral oil derivatives. They also work flawlessly in high pressure environments.

Major Synthetic Base Oils

- (PAO)

- Alkaline Aromatic

- Aliphatic Diester

- Polyester

- Polybutenes

- Phosphate Ester

- Polyalkenglycol

Synthetic oils, which are included in lubricants, are very costly products due to their raw materials and the use of high technology in their production. For this reason, synthetic oils are slightly more expensive compared to mineral oils. Thus, mineral oil prices vary in terms of the materials used in their production.

Where is Lube Oil Used?

Lubricant manufacturers have succeeded in producing lubricants with higher and higher viscosity ranges. These types of oils are very suitable options for businesses in many sectors.

It is possible to list the areas of use in terms of lubricants and their properties as follows.

- The lubricant utilizing liquid lubricants is very successful in the process of lubrication of the link and bearing rings in powder coating lines.

- They are used for the lubrication of machines used in packaging processes.

- The use of lubricants in machines operating in high temperature ranges is very humid. In this way, they contribute to extending the life of the machines.

- With their low viscosity, they are preferred as hydraulic lubricants in machines used in the pharmaceutical industry.

- They are used to lubricate the chains of machines operating in low temperature environments where there is a high probability of contact with food.

- Mineral oil is used in all closed circulation systems.

- They are used for lubrication of slide systems in gear couplings.

- They are used in closed systems operating under severe conditions, impact or load.

- They take an active role to meet the lubrication needs of the textile industry. They play an important role in the lubrication of stenter chains, especially in machines operating with automatic lubrication system.