SKU 320119

Category Oils

Mineral Compressor Oil

CORFIN COMP

Mineral Compressor Oil Advantages

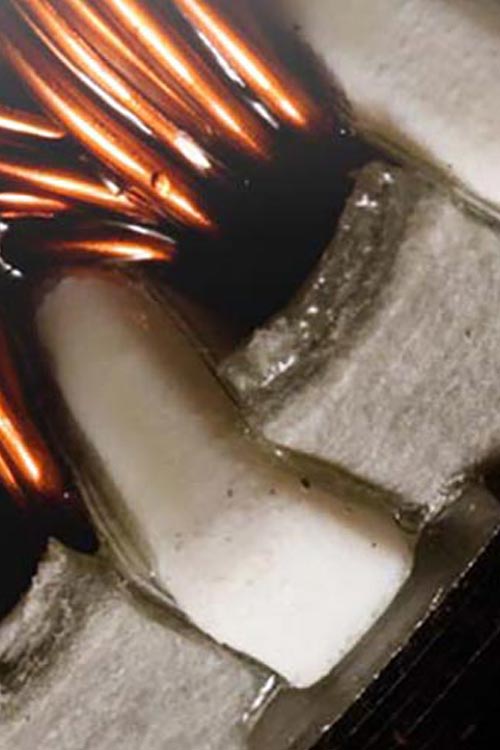

Mineral compressor oil Corfin Komp is a long-lasting and high quality product produced with the addition of a suitable additive package. It can be used successfully in the lubrication of many compressors of different structures. By forming a film layer on the metal surface, it prevents surface abrasion and provides protection against rust.

Corfin Comp is a high quality lubricant that optimally meets the cooling and sealing requirements of the equipment. Another important advantage of the lubricant is that it is a cleaner. In cases where dust enters the compressor and machine equipment, Corfin Komp collects these particles, carries them to the oil filter and returns them.

Thanks to its superior oxidation stability, it extends the service life even under difficult conditions.

Thanks to its low evaporation feature, it minimizes oil loss.

Excellent temperature stability even under high operating conditions.

Mineral Compressor Oil Features

- Advanced water and air separation capabilities ensure high performance.

- Extends the service life of filter elements.

- Prevents sediment formation with zinc-free technology.

- Provides high protection of the compressor against corrosion and abrasion.

- Extends oil change intervals

Mineral Compressor Oil Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

YOU MAY

ALSO

INTEREST

PRODUCTS

Mineral Compressor Oil Tech Data

| COMPRESSOR OIL ANALYSIS | STANDARD | 46 | 68 | 100 | |||||

| Appearance | Visual | Clear Bright | Clear Bright | Clear Bright | |||||

| Viscpsity (40 °C) | Viscpsity (40 °C) | 46 | 68 | 100 | |||||

| Viscosity Index | ASTM D2270 | Min. 100 | Min. 100 | Min. 100 | |||||

| Flash Point (°C) | ASTM 92 | Min. 200 | Min. 200 | Min. 200 | |||||

| Pour Point (°C) | ASTM D97 | < -20 | < -18 | < -15 | |||||

| Copper Corrosion (3h – 100 °C) | ASTM D130 | 1A | 1A | 1A | |||||

| Density (20°C-g/ml) | ASTM D1298 | 0,880 | 0,883 | 0,890 |

Mineral Compressor Oil Frequently Asked Questions

Contact Form

MADE IN

TÜRKİYE

FOR ALL ORDERS

FREE SHIPMENT

ON-SITE PROBLEM

DETECTION

TECHNICAL

CONSULTING

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.

SKU 320119

Category Oils

Mineral Compressor Oil

CORFIN COMP

CLASS OF USE

Compressor

BASE OIL

Paraffinic Mineral

VISCOSITY

46, 68, 100

208 L, 1000 L

1-3 Weeks

-

MADE IN

TÜRKİYE

-

FOR ALL ORDERS

FREE SHIPMENT

-

ON-SITE PROBLEM

DETECTION

-

TECHNICAL

CONSULTING

Mineral Compressor Oil Advantages

Mineral compressor oil Corfin Komp is a long-lasting and high quality product produced with the addition of a suitable additive package. It can be used successfully in the lubrication of many compressors of different structures. By forming a film layer on the metal surface, it prevents surface abrasion and provides protection against rust.

Corfin Comp is a high quality lubricant that optimally meets the cooling and sealing requirements of the equipment. Another important advantage of the lubricant is that it is a cleaner. In cases where dust enters the compressor and machine equipment, Corfin Komp collects these particles, carries them to the oil filter and returns them.

Thanks to its superior oxidation stability, it extends the service life even under difficult conditions.

Thanks to its low evaporation feature, it minimizes oil loss.

Excellent temperature stability even under high operating conditions.

Mineral Compressor Oil Features

- Advanced water and air separation capabilities ensure high performance.

- Extends the service life of filter elements.

- Prevents sediment formation with zinc-free technology.

- Provides high protection of the compressor against corrosion and abrasion.

- Extends oil change intervals

Mineral Compressor Oil Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

IN THESE PRODUCTS

YOU MAY BE INTERESTED

Mineral Compressor Oil Tech Data

| COMPRESSOR OIL ANALYSIS | STANDARD | 46 | 68 | 100 | |||||

| Appearance | Visual | Clear Bright | Clear Bright | Clear Bright | |||||

| Viscpsity (40 °C) | Viscpsity (40 °C) | 46 | 68 | 100 | |||||

| Viscosity Index | ASTM D2270 | Min. 100 | Min. 100 | Min. 100 | |||||

| Flash Point (°C) | ASTM 92 | Min. 200 | Min. 200 | Min. 200 | |||||

| Pour Point (°C) | ASTM D97 | < -20 | < -18 | < -15 | |||||

| Copper Corrosion (3h – 100 °C) | ASTM D130 | 1A | 1A | 1A | |||||

| Density (20°C-g/ml) | ASTM D1298 | 0,880 | 0,883 | 0,890 |

Mineral Compressor Oil Frequently Asked Questions

Contact Form

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.