SKU 320002

Category Oils

Mineral Hydraulic Oil

CORFIN HYDRO

Mineral Hydraulic Oil Advantages

It provides long-lasting lubrication and extends the lubrication period with its additives.

Provides superior protection against corrosion

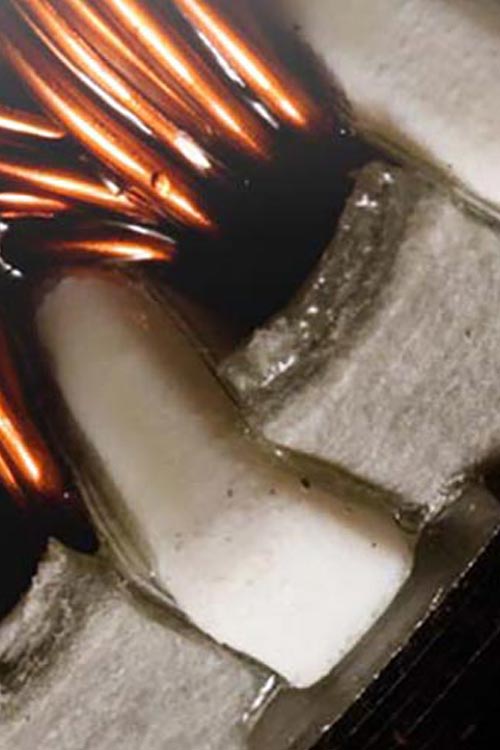

It is natural against metal surfaces to be used (does not affect parts such as copper, iron, elastomer etc.).

Mineral Hydraulic Oil Features

- Prevents abrasions

- Reduces friction

- High aging and oxidation resistance

- Does not form foam

- Easy separation from air and water

Mineral Hydraulic Oil Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

YOU MAY

ALSO

INTEREST

PRODUCTS

Mineral Hydraulic Oil Tech Data

| ANALYSIS | STANDARD | ISO VG 15 | ISO VG 22 | ISO VG 32 | ISO VG 46 | ISO VG 68 | ISO VG 100 | ISO VG 150 | |

| Color | Visual | Yellow | Yellow | Yellow | Yellow | Yellow | Yellow | Yellow | |

| Appearance | Visual | Clear Bright | Clear Bright | Clear Bright | Clear Bright | Clear Bright | Clear Bright | Clear Bright | |

| Viscpsity (40 °C) | ASTM D445 | 15 | 22 | 32 | 46 | 68 | 100 | 150 | |

| Viscosity Index | ASTM D2270 | 95 | 95 | 97 | >100 | >100 | >100 | >100 | |

| Flash Point (°C) | ASTM D92 | >210 | >210 | >210 | >210 | >220 | >220 | >220 | |

| Pour Point (°C) | ASTM D97 | ≤-30 | ≤-30 | ≤-30 | -25 | ≤-30 | ≤-30 | ≤-30 | |

| Copper Corrosion (3h-100°C) | ASTM D130 | 1a | 1a | 1a | 1a | 1a | 1a | 1a | |

| Foam Characteristics (24-93.5°C) | ASTM D892 | 5 - 0 | 5 - 0 | 5 - 0 | 10 - 0 | 10 - 0 | 10 - 0 | 10 - 0 | |

| Density (20°C-g/ml) | ASTM D1298 | 0,82 | 0,82 | 0,82 | 0,83 | 0,84 | 0,85 | 0,85 | |

| Rust Test | ASTM D665 | Pass | Pass | Pass | Pass | Pass | Pass | Pass | |

| TAN (maximum) mg KOH/g- | TS 9178 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 |

Mineral Hydraulic Oil Frequently Asked Questions

Log Splitters – The ramming mechanism in a hydraulic oil log splitter requires hydraulic fluid inside to provide the immense power that can split logs with ease. Auto Lifts – Auto lifts (jacks, car lifts, etc.) use hydraulic jack oil to help with their impressive power range. Snow Plows – Hydraulic oil for a snow plow and snow removal equipment is essential for the powerful operation of the hydraulic lifting, tilting and angling movements of the snow plow blade. Skid Steer Loaders – Skid steer hydraulic oil is as versatile as the machine it works with. Hydraulic oil plays a major role in the many tasks that this machine can competently perform. Aircraft (Aviation) – In the aviation industry, it is essential that aircraft hydraulic oil is reliable as it is used in aircraft control systems, aircraft hangar doors, aircraft jacks and aircraft controls. Aircraft – Aircraft and air compressors require high performance hydraulic oils with anti-wear additives for protection. Tractors – Tractor hydraulic oil is essential for the operation of hydraulic brakes and hydraulic systems in agricultural vehicles and equipment. Cruise Ships and Marine Industry – Many marine vessels use hydraulic oil for stabilizers. Stabilizers reduce the amount of rolling that can affect the stability of the ship and cause motion sickness. This is just one of many other applications that require hydraulic oil in marine vessels.

The different hydraulic fluid additives can be listed as follows. Antiwear – helps extend the life of equipment and machinery. Cold Flow – additives that allow use in extremely cold weather conditions. Anti-foam – an anti-foam agent for hydraulic oil reduces the foaming in the fluid that can be caused by detergents. This foaming can cause damage and reduce the lubricity of the product. Antioxidant – Reduces sludge buildup and allows longer use without oil changes. Rust inhibitor – Forms a protective coating that reduces the risk of rust damage caused by contact with oxygen. These additives are used alone and in combination in various blends designed for different purposes. Hydraulic oil properties can vary depending on the additives used, but typical properties tend to be high viscosity index and incompressibility.

Contact Form

MADE IN

TÜRKİYE

FOR ALL ORDERS

FREE SHIPMENT

ON-SITE PROBLEM

DETECTION

TECHNICAL

CONSULTING

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.

SKU 320002

Category Oils

Mineral Hydraulic Oil

CORFIN HYDRO

CLASS OF USE

Hydraulics

BASE OIL

Paraffinic Mineral

VISCOSITY

15, 22, 32, 37, 46, 68, 100, 150

208 L, 1000 L

1-3 Weeks

-

MADE IN

TÜRKİYE

-

FOR ALL ORDERS

FREE SHIPMENT

-

ON-SITE PROBLEM

DETECTION

-

TECHNICAL

CONSULTING

Mineral Hydraulic Oil Advantages

It provides long-lasting lubrication and extends the lubrication period with its additives.

Provides superior protection against corrosion

It is natural against metal surfaces to be used (does not affect parts such as copper, iron, elastomer etc.).

Mineral Hydraulic Oil Features

- Prevents abrasions

- Reduces friction

- High aging and oxidation resistance

- Does not form foam

- Easy separation from air and water

Mineral Hydraulic Oil Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

IN THESE PRODUCTS

YOU MAY BE INTERESTED

Mineral Hydraulic Oil Tech Data

| ANALYSIS | STANDARD | ISO VG 15 | ISO VG 22 | ISO VG 32 | ISO VG 46 | ISO VG 68 | ISO VG 100 | ISO VG 150 | |

| Color | Visual | Yellow | Yellow | Yellow | Yellow | Yellow | Yellow | Yellow | |

| Appearance | Visual | Clear Bright | Clear Bright | Clear Bright | Clear Bright | Clear Bright | Clear Bright | Clear Bright | |

| Viscpsity (40 °C) | ASTM D445 | 15 | 22 | 32 | 46 | 68 | 100 | 150 | |

| Viscosity Index | ASTM D2270 | 95 | 95 | 97 | >100 | >100 | >100 | >100 | |

| Flash Point (°C) | ASTM D92 | >210 | >210 | >210 | >210 | >220 | >220 | >220 | |

| Pour Point (°C) | ASTM D97 | ≤-30 | ≤-30 | ≤-30 | -25 | ≤-30 | ≤-30 | ≤-30 | |

| Copper Corrosion (3h-100°C) | ASTM D130 | 1a | 1a | 1a | 1a | 1a | 1a | 1a | |

| Foam Characteristics (24-93.5°C) | ASTM D892 | 5 - 0 | 5 - 0 | 5 - 0 | 10 - 0 | 10 - 0 | 10 - 0 | 10 - 0 | |

| Density (20°C-g/ml) | ASTM D1298 | 0,82 | 0,82 | 0,82 | 0,83 | 0,84 | 0,85 | 0,85 | |

| Rust Test | ASTM D665 | Pass | Pass | Pass | Pass | Pass | Pass | Pass | |

| TAN (maximum) mg KOH/g- | TS 9178 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 |

Mineral Hydraulic Oil Frequently Asked Questions

Log Splitters – The ramming mechanism in a hydraulic oil log splitter requires hydraulic fluid inside to provide the immense power that can split logs with ease. Auto Lifts – Auto lifts (jacks, car lifts, etc.) use hydraulic jack oil to help with their impressive power range. Snow Plows – Hydraulic oil for a snow plow and snow removal equipment is essential for the powerful operation of the hydraulic lifting, tilting and angling movements of the snow plow blade. Skid Steer Loaders – Skid steer hydraulic oil is as versatile as the machine it works with. Hydraulic oil plays a major role in the many tasks that this machine can competently perform. Aircraft (Aviation) – In the aviation industry, it is essential that aircraft hydraulic oil is reliable as it is used in aircraft control systems, aircraft hangar doors, aircraft jacks and aircraft controls. Aircraft – Aircraft and air compressors require high performance hydraulic oils with anti-wear additives for protection. Tractors – Tractor hydraulic oil is essential for the operation of hydraulic brakes and hydraulic systems in agricultural vehicles and equipment. Cruise Ships and Marine Industry – Many marine vessels use hydraulic oil for stabilizers. Stabilizers reduce the amount of rolling that can affect the stability of the ship and cause motion sickness. This is just one of many other applications that require hydraulic oil in marine vessels.

The different hydraulic fluid additives can be listed as follows. Antiwear – helps extend the life of equipment and machinery. Cold Flow – additives that allow use in extremely cold weather conditions. Anti-foam – an anti-foam agent for hydraulic oil reduces the foaming in the fluid that can be caused by detergents. This foaming can cause damage and reduce the lubricity of the product. Antioxidant – Reduces sludge buildup and allows longer use without oil changes. Rust inhibitor – Forms a protective coating that reduces the risk of rust damage caused by contact with oxygen. These additives are used alone and in combination in various blends designed for different purposes. Hydraulic oil properties can vary depending on the additives used, but typical properties tend to be high viscosity index and incompressibility.

Contact Form

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.