SKU 800005

Category Oils

Pharmaceutical - Food Industry Lubricant

UNIVER H1 NFC

Pharmaceutical - Food Industry Lubricant Advantages

Lubricant for the Pharmaceutical and Food Industry, is particularly resistant to aging and oxidation. It has good viscosity-temperature behavior and excellent low and high temperature properties. It also provides good corrosion protection and is neutral towards non-ferrous metals, elastomers and internal paints used in gear systems. Therefore, they increase the efficiency of the system in which they are used. Since it does not foam, it does not cause oil leakage from the seals in the systems where it is used.

It does not foam and has high protection against oxidation and corrosion.

Registered as NSF H1 for use in the food processing and pharmaceutical industries.

Thanks to its fully synthetic base oil, it provides a long service life due to its high viscosity index during temperature changes.

Pharmaceutical - Food Industry Lubricant Features

- Its wide viscosity range makes it suitable for many applications of businesses.

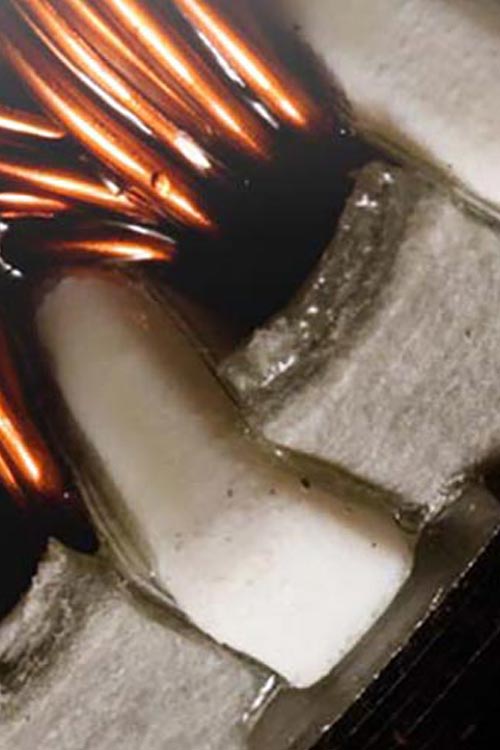

- It is used in all types of closed gear and circulation systems.

- Anti-corrosion structure.

- Maximum performance at high and low temperatures.

- Increasing efficiency in application areas.

Pharmaceutical - Food Industry Lubricant Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

YOU MAY

ALSO

INTEREST

PRODUCTS

Pharmaceutical - Food Industry Lubricant Tech Data

| ANALYSIS | 32 | 46 | 68 | 100 | 150 | 220 | 320 | 460 | 680 |

| Viscosity (40 °C) ASTM D445 | 32 | 46 | 68 | 100 | 150 | 220 | 320 | 460 | 680 |

| Viscosity Index ASTM D2270 | >135 | >135 | >135 | >140 | >150 | >150 | >150 | >150 | >150 |

| Flash Point (°C) ASTM D92 | >230 | >230 | >230 | >230 | >250 | >250 | >250 | >250 | >250 |

| Pour Point ASTM D97 (°C) | <-42 | <-40 | <-38 | <-35 | <-35 | <-30 | <-28 | <-25 | <-25 |

| Copper Corrosion (3 hours - 100 °C) ASTM D130 | 1 A | 1 A | 1 A | 1 A | 1 A | 1 A | 1 A | 1 A | 1 A |

| Foam Characteristic (24 - 93.5 °C) ASTM D892 | 5-0 | 5-0 | 5-0 | 10-0 | 10-0 | 10-0 | 10-0 | 10-0 | 10-0 |

| Density (20 °C - g/ml) ASTM D1298 | 0,83 | 0,83 | 0,83 | 0,84 | 0,86 | 0,86 | 0,86 | 0,88 | 0,9 |

| Rust Test (40 °C) ASTM D665 | Pass | Pass | Pass | Pass | Pass | Pass | Pass | Pass | Pass |

Pharmaceutical - Food Industry Lubricant Frequently Asked Questions

Contact Form

MADE IN

TÜRKİYE

FOR ALL ORDERS

FREE SHIPMENT

ON-SITE PROBLEM

DETECTION

TECHNICAL

CONSULTING

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.

SKU 800005

Category Oils

Pharmaceutical - Food Industry Lubricant

UNIVER H1 NFC

CLASS OF USE

Food (NSF) Approved

BASE OIL

Synthetic

VISCOSITY

32, 46, 68, 100, 150, 220, 320, 460, 680

20 L, 200 L, 1000 L

1-3 Weeks

-

MADE IN

TÜRKİYE

-

FOR ALL ORDERS

FREE SHIPMENT

-

ON-SITE PROBLEM

DETECTION

-

TECHNICAL

CONSULTING

Pharmaceutical - Food Industry Lubricant Advantages

Lubricant for the Pharmaceutical and Food Industry, is particularly resistant to aging and oxidation. It has good viscosity-temperature behavior and excellent low and high temperature properties. It also provides good corrosion protection and is neutral towards non-ferrous metals, elastomers and internal paints used in gear systems. Therefore, they increase the efficiency of the system in which they are used. Since it does not foam, it does not cause oil leakage from the seals in the systems where it is used.

It does not foam and has high protection against oxidation and corrosion.

Registered as NSF H1 for use in the food processing and pharmaceutical industries.

Thanks to its fully synthetic base oil, it provides a long service life due to its high viscosity index during temperature changes.

Pharmaceutical - Food Industry Lubricant Features

- Its wide viscosity range makes it suitable for many applications of businesses.

- It is used in all types of closed gear and circulation systems.

- Anti-corrosion structure.

- Maximum performance at high and low temperatures.

- Increasing efficiency in application areas.

Pharmaceutical - Food Industry Lubricant Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

IN THESE PRODUCTS

YOU MAY BE INTERESTED

Pharmaceutical - Food Industry Lubricant Tech Data

| ANALYSIS | 32 | 46 | 68 | 100 | 150 | 220 | 320 | 460 | 680 |

| Viscosity (40 °C) ASTM D445 | 32 | 46 | 68 | 100 | 150 | 220 | 320 | 460 | 680 |

| Viscosity Index ASTM D2270 | >135 | >135 | >135 | >140 | >150 | >150 | >150 | >150 | >150 |

| Flash Point (°C) ASTM D92 | >230 | >230 | >230 | >230 | >250 | >250 | >250 | >250 | >250 |

| Pour Point ASTM D97 (°C) | <-42 | <-40 | <-38 | <-35 | <-35 | <-30 | <-28 | <-25 | <-25 |

| Copper Corrosion (3 hours - 100 °C) ASTM D130 | 1 A | 1 A | 1 A | 1 A | 1 A | 1 A | 1 A | 1 A | 1 A |

| Foam Characteristic (24 - 93.5 °C) ASTM D892 | 5-0 | 5-0 | 5-0 | 10-0 | 10-0 | 10-0 | 10-0 | 10-0 | 10-0 |

| Density (20 °C - g/ml) ASTM D1298 | 0,83 | 0,83 | 0,83 | 0,84 | 0,86 | 0,86 | 0,86 | 0,88 | 0,9 |

| Rust Test (40 °C) ASTM D665 | Pass | Pass | Pass | Pass | Pass | Pass | Pass | Pass | Pass |

Pharmaceutical - Food Industry Lubricant Frequently Asked Questions

Contact Form

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.