SKU 320136

Category Oils

Protective Oil

CORFIN WE 501

Protective Oil Advantages

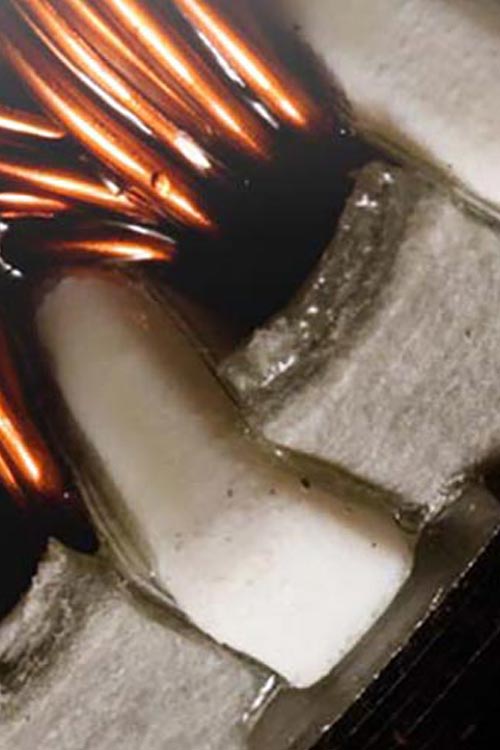

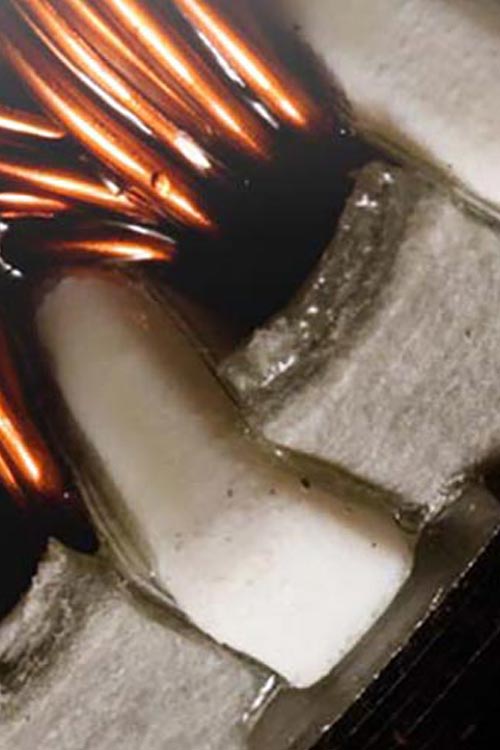

It is a rust inhibitor that provides medium-term protection against rust on metal surfaces during use or storage. It is a solvent-based, water-repellent rust inhibitor that leaves a waxy coating on metal surfaces. The product protects metal surfaces from the damaging effects of moisture, air, detergents and other contaminants. It is applied by dipping or spraying. In both methods it provides full performance protection after application. It insulates up to 55,000 volts in electric motors. It is effective in long term problem free operation of the equipment. Provides medium lubrication and protection.

Effective in preventing corrosion.

Provides medium term rust protection.

Repels water and leaves a waxy film on the surface.

Protective Oil Features

- After its application, it acts as a lubricant as well as a protector.

- Prevents major equipment damage.

- Minimizes product loss and equipment downtime.

- Quickly penetrates small cracks and pores.

- Eliminates additional equipment operating costs.

Protective Oil Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

YOU MAY

ALSO

INTEREST

PRODUCTS

Protective Oil Tech Data

Protective Oil Frequently Asked Questions

These thin films age poorly and can easily crack and flake, leaving exposed surfaces. Corfin We 501 Protective Oil pure and hybrid polyureas and polyurethanes are designed to withstand abrasion, high impact, extreme temperatures, chemicals, water and many other environments for a wide range of applications. These polymers resist compression and flex without cracking, even when the underlying structure changes or vibrates. The impermeable nature of these materials creates a seamless, leak-proof barrier.

Contact Form

MADE IN

TÜRKİYE

FOR ALL ORDERS

FREE SHIPMENT

ON-SITE PROBLEM

DETECTION

TECHNICAL

CONSULTING

THE BENEFITS OF PROTECTIVE OIL

It is a rust inhibitor that provides medium-term protection against rust on metal surfaces during use or storage. It is a solvent-based, water-repellent rust inhibitor that leaves a waxy film on metal surfaces. The product protects metal surfaces from the damaging effects of moisture, air, detergents and other contaminants. It is applied by dipping and spraying. It insulates up to 55,000 volts in electric motors.

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.

SKU 320136

Category Oils

Protective Oil

CORFIN WE 501

CLASS OF USE

Protection

BASE OIL

Other

20 L, 200 L

1-3 Weeks

-

MADE IN

TÜRKİYE

-

FOR ALL ORDERS

FREE SHIPMENT

-

ON-SITE PROBLEM

DETECTION

-

TECHNICAL

CONSULTING

Protective Oil Advantages

It is a rust inhibitor that provides medium-term protection against rust on metal surfaces during use or storage. It is a solvent-based, water-repellent rust inhibitor that leaves a waxy coating on metal surfaces. The product protects metal surfaces from the damaging effects of moisture, air, detergents and other contaminants. It is applied by dipping or spraying. In both methods it provides full performance protection after application. It insulates up to 55,000 volts in electric motors. It is effective in long term problem free operation of the equipment. Provides medium lubrication and protection.

Effective in preventing corrosion.

Provides medium term rust protection.

Repels water and leaves a waxy film on the surface.

Protective Oil Features

- After its application, it acts as a lubricant as well as a protector.

- Prevents major equipment damage.

- Minimizes product loss and equipment downtime.

- Quickly penetrates small cracks and pores.

- Eliminates additional equipment operating costs.

Protective Oil Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

IN THESE PRODUCTS

YOU MAY BE INTERESTED

Protective Oil Tech Data

Protective Oil Frequently Asked Questions

These thin films age poorly and can easily crack and flake, leaving exposed surfaces. Corfin We 501 Protective Oil pure and hybrid polyureas and polyurethanes are designed to withstand abrasion, high impact, extreme temperatures, chemicals, water and many other environments for a wide range of applications. These polymers resist compression and flex without cracking, even when the underlying structure changes or vibrates. The impermeable nature of these materials creates a seamless, leak-proof barrier.

Contact Form

THE BENEFITS OF PROTECTIVE OIL

It is a rust inhibitor that provides medium-term protection against rust on metal surfaces during use or storage. It is a solvent-based, water-repellent rust inhibitor that leaves a waxy film on metal surfaces. The product protects metal surfaces from the damaging effects of moisture, air, detergents and other contaminants. It is applied by dipping and spraying. It insulates up to 55,000 volts in electric motors.

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.