SKU 320249

Category Oils

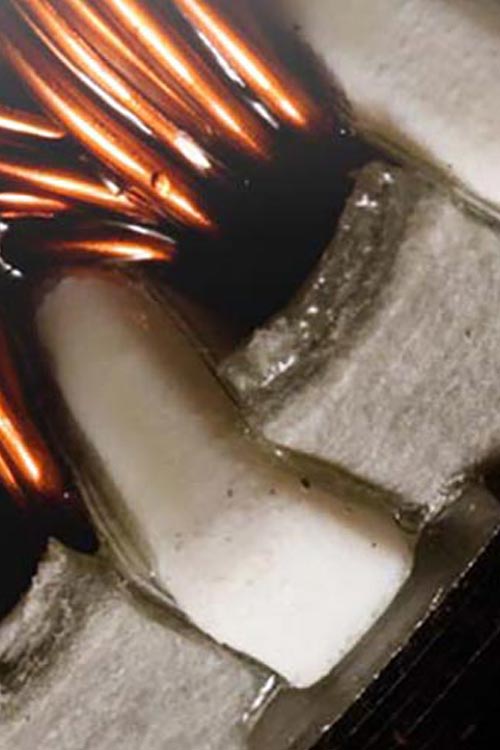

Texture Yarn Oil

AKOLUBE 1002

Texture Yarn Oil Advantages

It is easily washed after the weaving process. It ensures easy washing and combing of yarns and lubrication of spinning machines, reduces friction and improves product quality. Reduces static electricity accumulation. It emulsifies easily and its washing properties are superior. Since it has a controlled viscosity range, its friction value is high. It does not damage needles and spools, which have an important place in production.

It provides lubricity by reducing friction during the process.

It prevents the formation of static charge during weaving.

It is corrosion resistant and does not damage the needles.

Texture Yarn Oil Features

- They exhibit superior performance even at high speeds.

- It works compatible with all kinds of textile products.

- It provides extra slipperiness to minimize friction.

- It meets the demands required in yarn production in the best way.

- It does not leave any stains on the threads and is easily washed.

Texture Yarn Oil Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

YOU MAY

ALSO

INTEREST

PRODUCTS

Texture Yarn Oil Tech Data

| YARN OIL ANALYSIS | STANDARD | 1002 | |||||||

| Color | Visual | Light Yellow | |||||||

| Appearance | Visual | Clear Bright | |||||||

| Viscpsity (40 °C) | ASTM D445 | 27-30 | |||||||

| Viscosity Index | ASTM D2270 | 95 | |||||||

| Flash Point (°C) | ASTM 92 | >200 | |||||||

| Pour Point (°C) | ASTM D97 | <-5 | |||||||

| Copper Corrosion (3h – 100 °C) | ASTM D130 | 1a | |||||||

| Density (20°C-g/ml) | ASTM D1298 | 0,84 |

Texture Yarn Oil Frequently Asked Questions

Contact Form

MADE IN

TÜRKİYE

FOR ALL ORDERS

FREE SHIPMENT

ON-SITE PROBLEM

DETECTION

TECHNICAL

CONSULTING

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.

SKU 320249

Category Oils

Texture Yarn Oil

AKOLUBE 1002

CLASS OF USE

Textile

BASE OIL

Paraffinic Mineral

VISCOSITY

27-30

20 L, 208 L, 1000 L

1-3 Weeks

-

MADE IN

TÜRKİYE

-

FOR ALL ORDERS

FREE SHIPMENT

-

ON-SITE PROBLEM

DETECTION

-

TECHNICAL

CONSULTING

Texture Yarn Oil Advantages

It is easily washed after the weaving process. It ensures easy washing and combing of yarns and lubrication of spinning machines, reduces friction and improves product quality. Reduces static electricity accumulation. It emulsifies easily and its washing properties are superior. Since it has a controlled viscosity range, its friction value is high. It does not damage needles and spools, which have an important place in production.

It provides lubricity by reducing friction during the process.

It prevents the formation of static charge during weaving.

It is corrosion resistant and does not damage the needles.

Texture Yarn Oil Features

- They exhibit superior performance even at high speeds.

- It works compatible with all kinds of textile products.

- It provides extra slipperiness to minimize friction.

- It meets the demands required in yarn production in the best way.

- It does not leave any stains on the threads and is easily washed.

Texture Yarn Oil Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

IN THESE PRODUCTS

YOU MAY BE INTERESTED

Texture Yarn Oil Tech Data

| YARN OIL ANALYSIS | STANDARD | 1002 | |||||||

| Color | Visual | Light Yellow | |||||||

| Appearance | Visual | Clear Bright | |||||||

| Viscpsity (40 °C) | ASTM D445 | 27-30 | |||||||

| Viscosity Index | ASTM D2270 | 95 | |||||||

| Flash Point (°C) | ASTM 92 | >200 | |||||||

| Pour Point (°C) | ASTM D97 | <-5 | |||||||

| Copper Corrosion (3h – 100 °C) | ASTM D130 | 1a | |||||||

| Density (20°C-g/ml) | ASTM D1298 | 0,84 |

Texture Yarn Oil Frequently Asked Questions

Contact Form

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.